|

|

|

|

|

|

|

|

|

|

| |

오늘방문자 : 304 |

| |

전체방문자 : 117,476명 |

|

|

|

|

|

|

Portable, reliable, and accurate: Balanset-1 |

닉네임 |

|

EQiblyMar |

|

작성일/조회 |

|

2024-12-24 / 138회 |

|

첨부파일 |

|

첨부파일이 없습니다. |

|

|

|

|

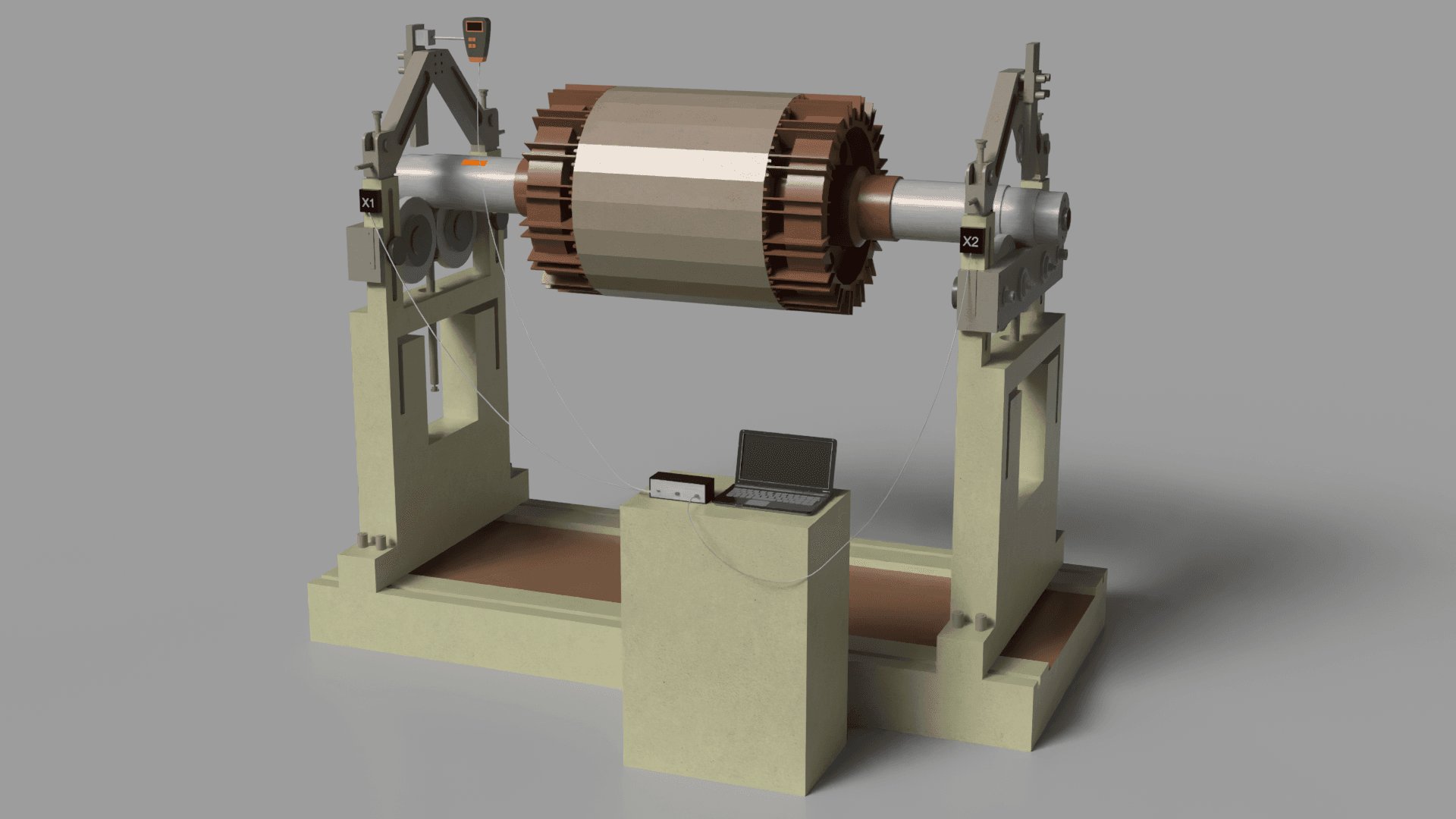

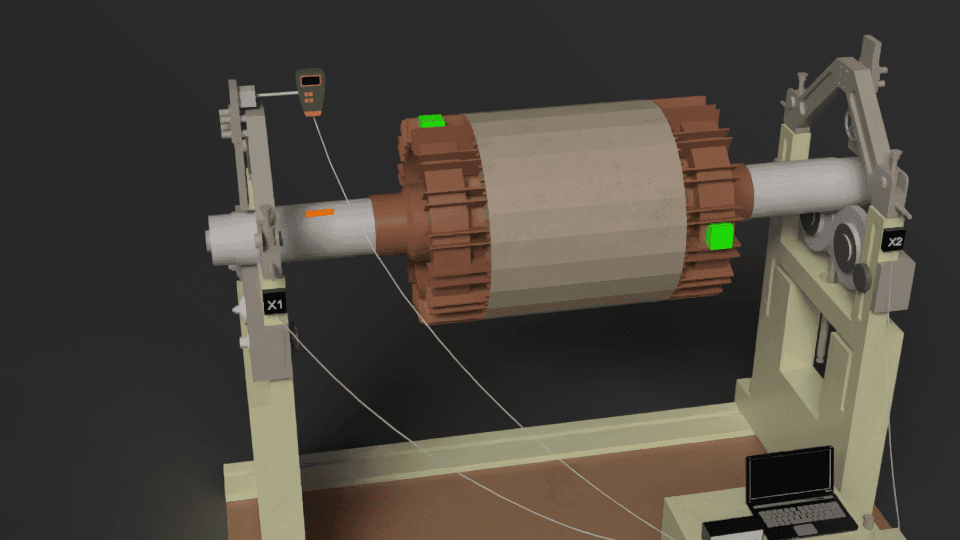

with the Balanset-1A Device

Preparing the Necessary Tools

- accelerometers, laser rpm sensor, mounting stand, software application, and additional tools.

- Establish a USB connection between the instrument and the computer, ensuring the software is set up properly.

Sensor Installation

- Mount the vibration transducers securely on the machine's housing where vibrations are most pronounced, typically near the bearings.

- Direct the laser speed sensor towards the rotor and affix reflective tape to the rotor surface to facilitate phase angle measurement.

Starting the Program

- Initiate the Balanset program on your computer.

- Choose the correct balancing method (single or two-plane) according to the rotor configuration and the balancing task.

- Bring the rotor to its normal operating rotational frequency.

- The program will record the vibration amplitude, rpm, and phase, providing a baseline measurement of the existing imbalance.

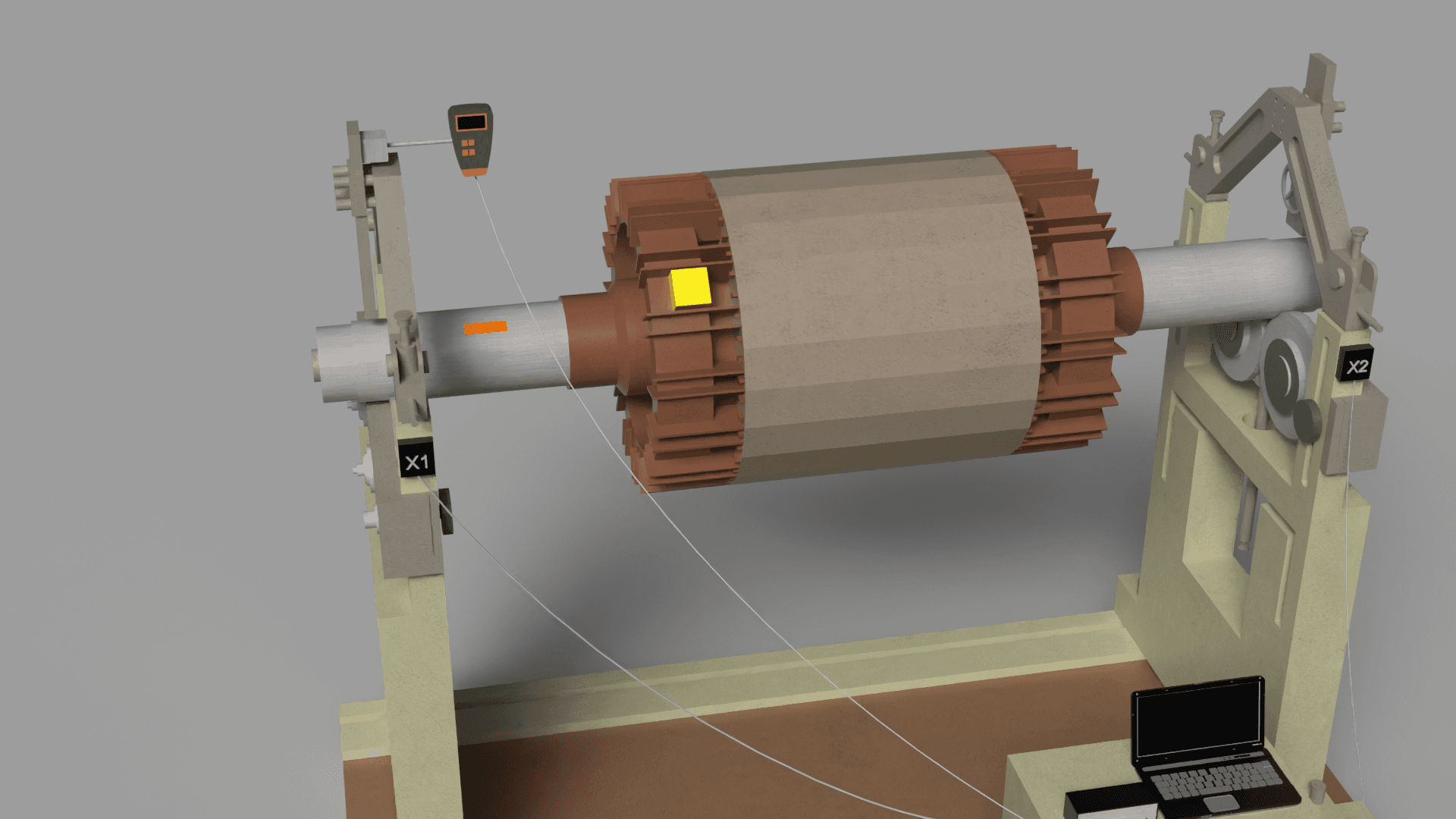

Mounting the Test Weight

- Bring the rotor to a standstill and affix a trial weight at a predetermined point on the rotor, specifying its mass in the software (typically in grams).

- Restart the rotor, and the software will record the changes in vibration level and phase angle.

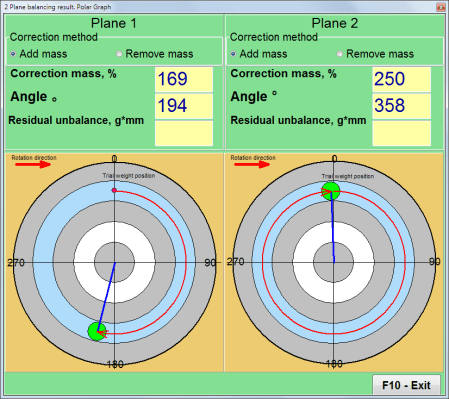

Calculating the Correction Weight

- The software uses the measured values to automatically compute the necessary compensating weight's magnitude and placement angle.

- The results of the calculation are shown both numerically and visually through charts and graphs.

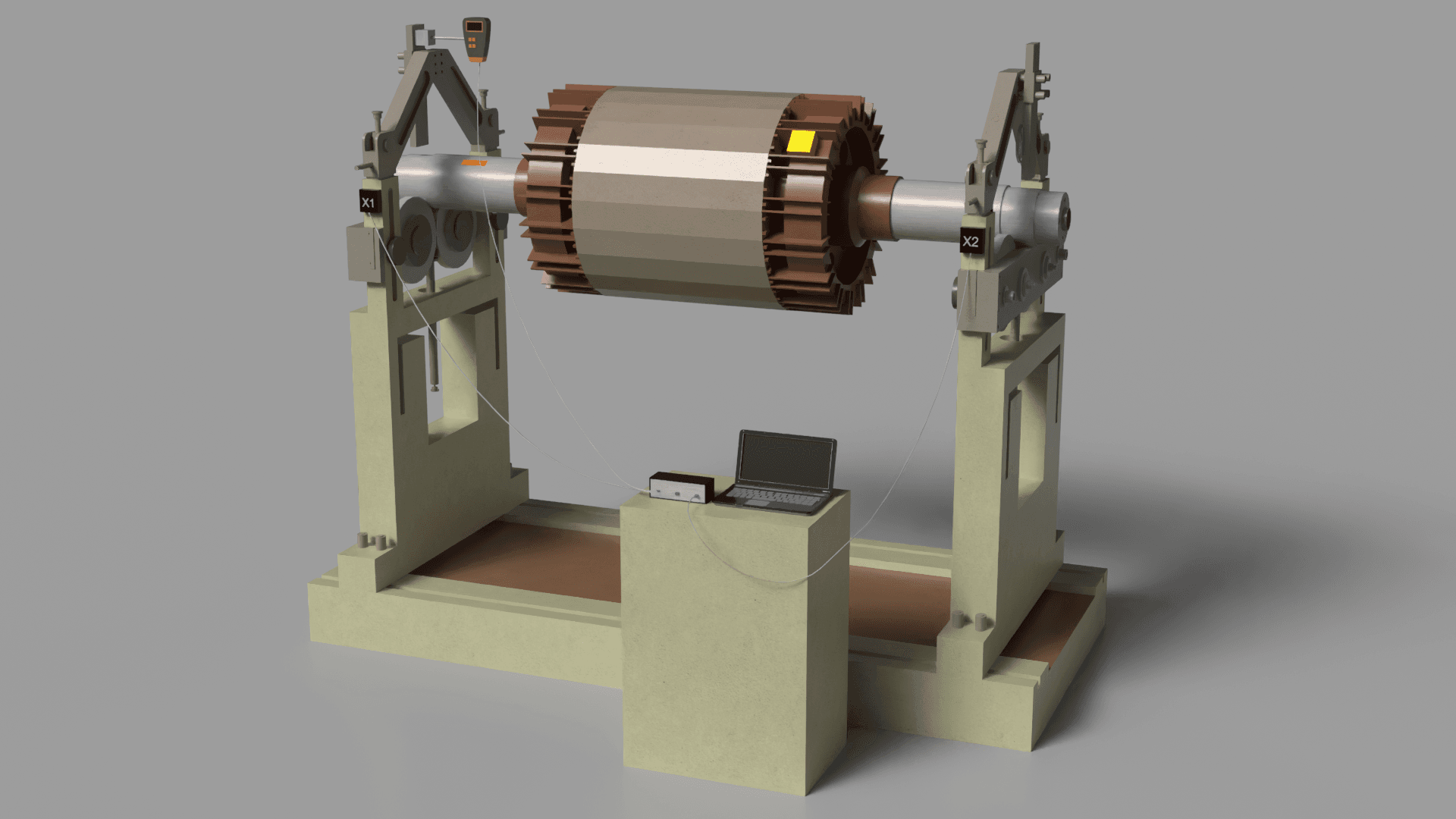

Installing the Correction Weight

- Attach the computed compensating weight to the rotor as indicated by the software's output.

- Periodic checks can be performed to ensure the balancing procedure is effectively reducing the vibration.

Verification and Balancing Completion

- Once the corrective weight is in place, restart the rotor and measure the remaining vibration amplitude.

- The balancing procedure is finished if the remaining vibration is within the permissible limits specified in ISO 1940.

- If the vibration level remains high, repeat the process with further weight adjustments.

Creating a Balancing Report

- The program stores the balancing data, allowing you to generate and print a comprehensive report including vibration measurements, corrective weight details, and its angular placement.

Concluding Steps and Verification

- Double-check that all weights and sensors are securely fastened.

- Check that the rotor's rotation is smooth and free from undue noise or vibration.

- In cases where the rotor is integrated into a more complex system, ensure the correct operation and interaction of all related components.

By implementing this method, you can effectively eliminate imbalance, reduce vibration levels, and increase the lifespan of the machinery.

Instagram: https://www.instagram.com/vibromera_ou/

Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL

Our website about Scrubber balancing

Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal

Facebook: https://www.facebook.com/marketplace/item/350151228150722

|

| |

|

|

|

|

|

|

|

|

|